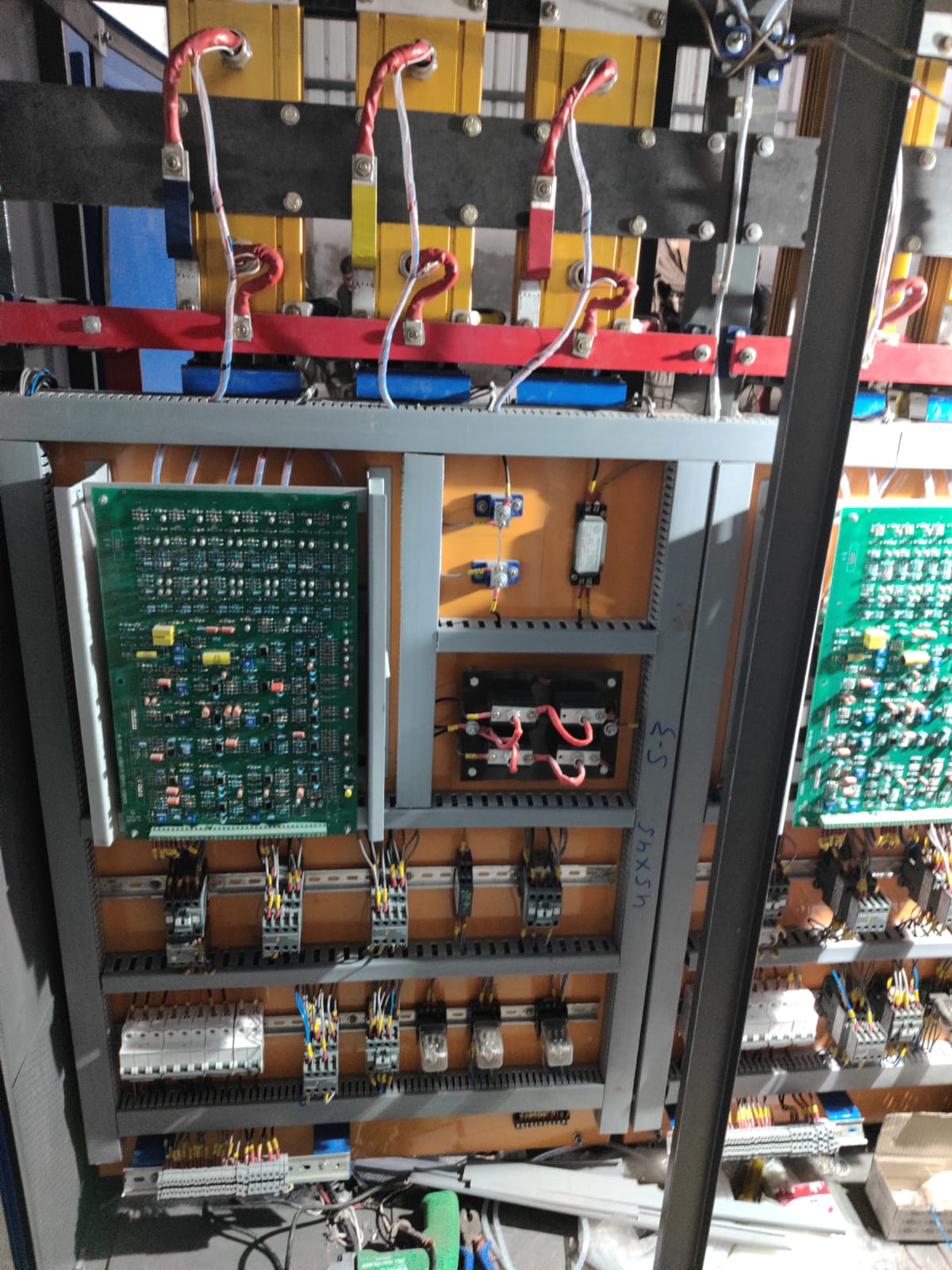

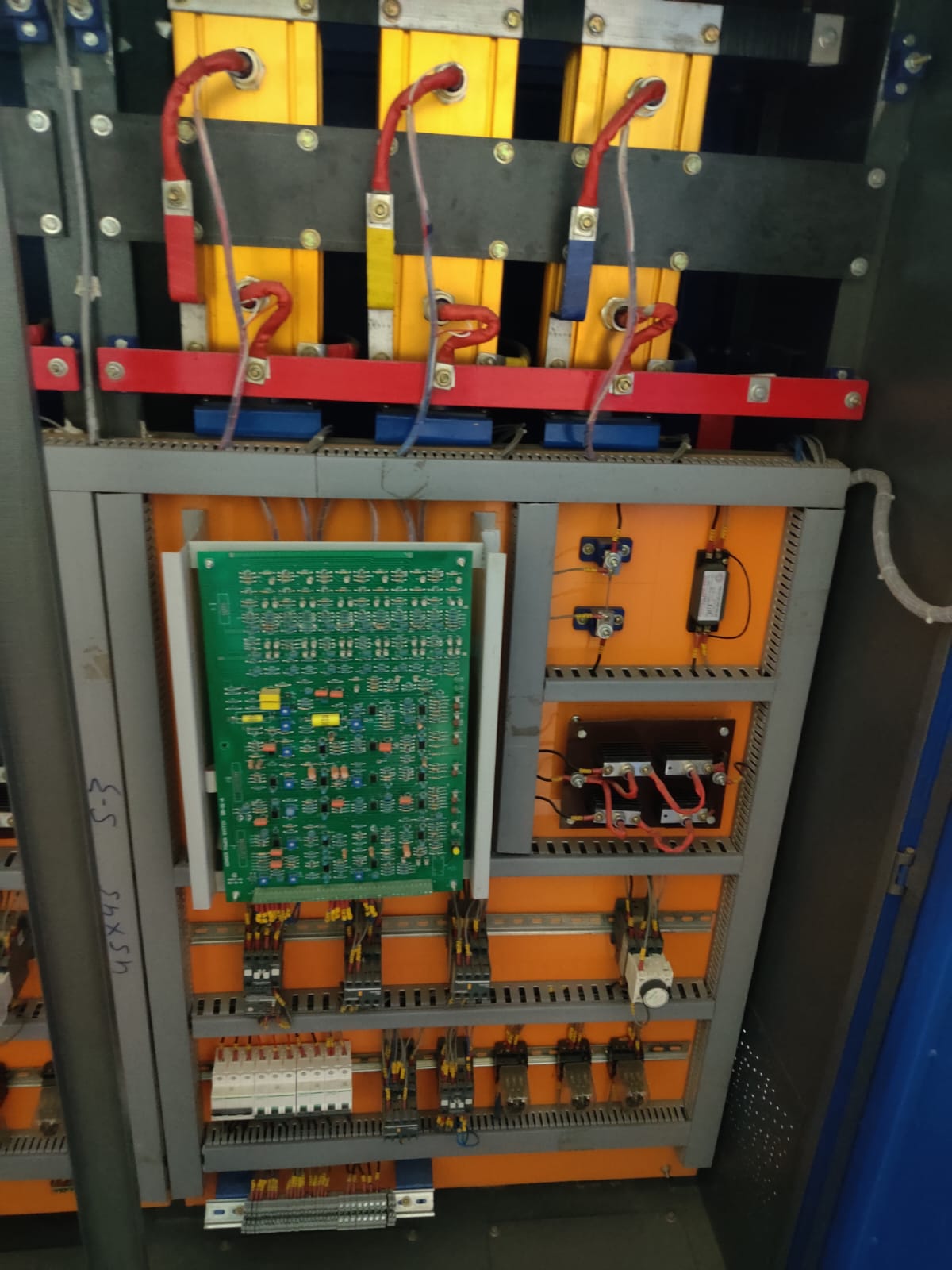

SHORT DESCRIPTION:

DC motor panels play a crucial role in the efficient operation of tube mills and slitting lines in industrial settings. These panels are designed to control and regulate the speed and torque of DC motors, ensuring precise and reliable performance during the production processes.

In tube mills, DC motor panels are responsible for driving the various components involved in the tube production, such as the conveyor systems, rollers, and cutting mechanisms. The ability to finely tune the motor speed is essential for maintaining consistent tube dimensions and quality. The panels incorporate advanced control features, allowing operators to adjust parameters like speed and torque to meet specific production requirements.

Similarly, in slitting lines, DC motor panels are instrumental in driving the slitter blades and managing the tension of the material being processed. This level of control is crucial for achieving accurate slitting and maintaining the integrity of the final product. The panels also contribute to minimizing downtime and optimizing energy efficiency.

The integration of modern technologies, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs), enhances the functionality of DC motor panels, providing operators with user-friendly interfaces for monitoring and controlling the entire system. Ultimately, these panels contribute to the overall efficiency, precision, and reliability of tube mills and slitting lines in the metalworking industry.