SHORT DESCRIPTION:

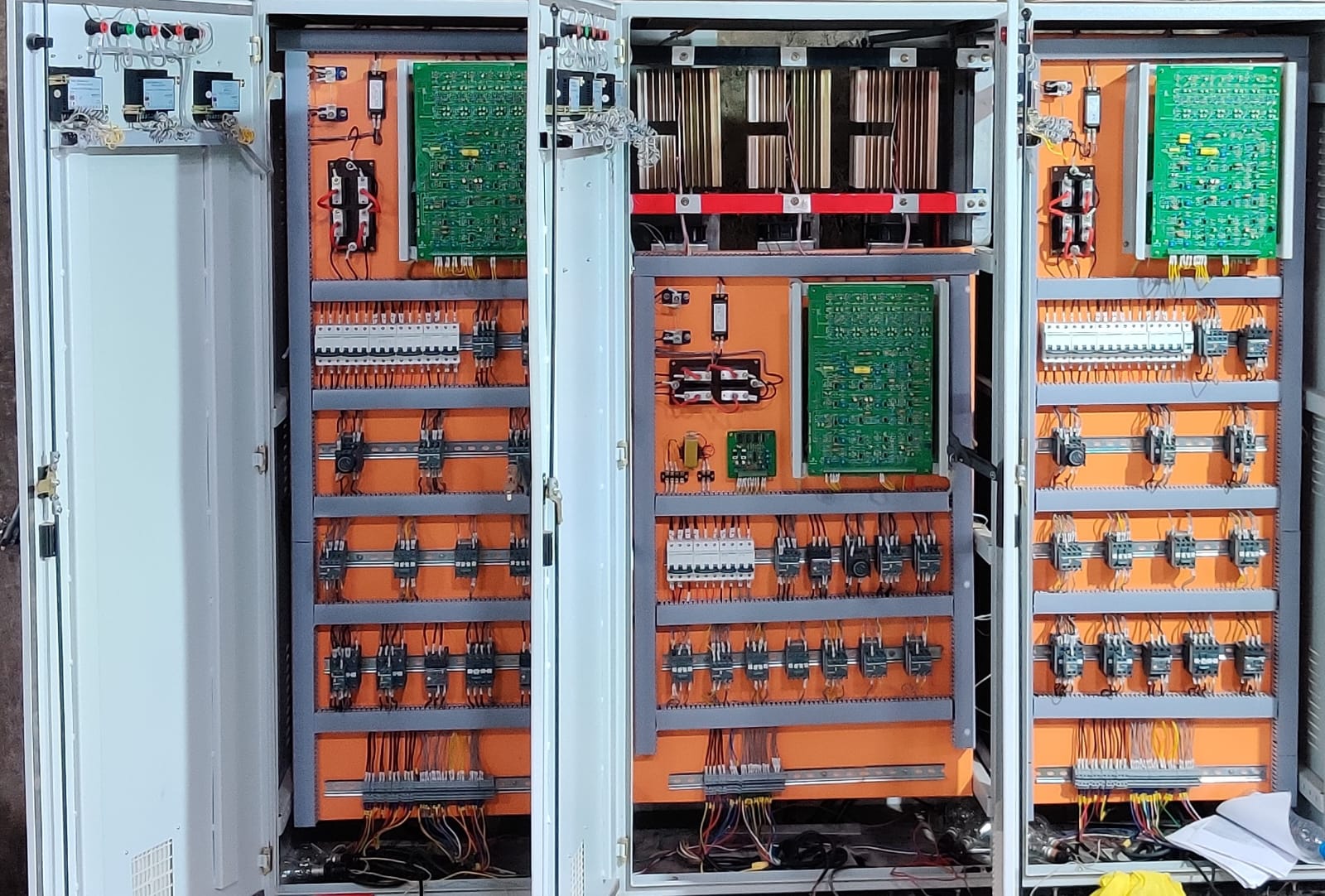

Hot and cold rolling mills play a crucial role in the metal processing industry, shaping metal sheets and bars into desired forms through a series of rolling processes. The DC motor panels employed in these mills are integral components for driving and controlling the various stages of rolling.

In hot rolling mills, DC motor panels are responsible for driving the rollers that shape heated metal into sheets or other configurations. These panels regulate the speed and torque of the DC motors, allowing for precise control over the rolling process. This control is vital to achieve the desired thickness, surface finish, and overall quality of the rolled metal.

Similarly, in cold rolling mills, DC motor panels are utilized to control the motors that process metal at lower temperatures, enhancing its mechanical properties and surface finish. The ability to adjust the motor speed and torque through these panels ensures the accurate reduction of thickness and the achievement of specific dimensional tolerances.

These motor panels incorporate advanced control systems to manage the complexities of the rolling process. They often feature feedback mechanisms, such as encoders, to provide real-time data for optimal control and monitoring. The reliability and efficiency of these DC motor panels are critical for the overall productivity and quality of output in hot and cold rolling mills, making them essential components in metal manufacturing.